Product Styles

Contact Us About Creating Custom Floss And Dispenser Colors

Design Features

Get to know about our floss

Floss Materials

Our regular floss materials include round-shaped polyester thread, round-shaped nylon thread, round-shaped polyester charcoal thread, and PTFE (Polytetrafluoroethylene) thread. Other materials are available upon request.

Floss Lengths

Depending on choice of floss containers, we offer floss lengths of 10, 50, and 60 meters. Other floss lengths are available for cardboard dispenser packaging upon request.

Floss Colors

Our floss’s natural color is semi-transparent to white prior to flavor coating. After flavor coating, the floss color changes slightly depending on the flavor chosen for coating.

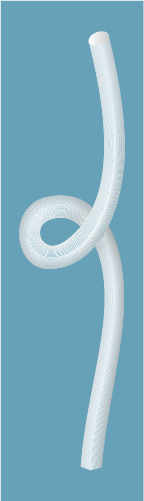

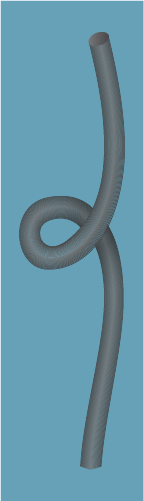

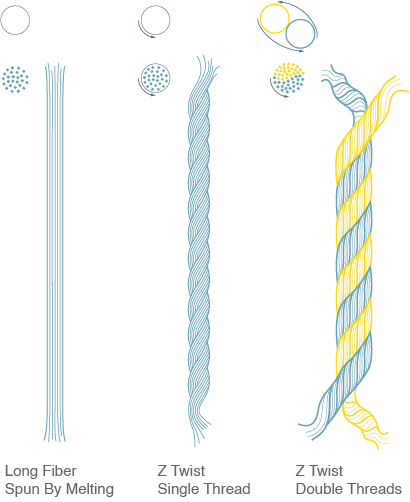

Floss Twisting

We offer various floss twist and denier (D) specifications. For our polyester thread, polyester nylon thread, and polyethylene thread, we apply the Z twist technique. The Z twist helps strengthens the fibers together and will not untwist easily and is correlated to the diameter of a single floss strand. Typically, the larger the Z, the thicker the thread and vice versa. For our denier specifications, we offer a variety of denier threads ranging from 150D to 1050D. Denier refers to weight in grams of 9,000 meters of thread. Typically, the larger the denier, the heavier the thread, and it provides higher elasticity. On the other hand, the smaller the denier, the lighter the thread, and it gives the thread a smoother and more transparent finish. Depending on your clientele and market needs, we provide a variety of floss specifications for your choosing.

Floss Flavor Coating

All our floss flavor formulas are made in-house and the floss coatings are applied with rigorous coating SOPs at our automated production lines.

For our floss dispenser products, we provide the following flavors and coatings: green tea, strawberry, mint, and fluoride. We offer two main types of finishing other than flavor: unwaxed floss and waxed floss. Unwaxed floss can be prone to shredding or breaking and the finished look may be looser since the bonding additive wax is missing. As for waxed floss, it is less likely to break, however, wax coating may make it harder to use in tighter teeth spots since it creates a slightly higher friction between teeth than unwaxed floss.

Depending on the needs of your target clientele and markets, we can create your desired floss flavor formula for you.

How To Select Your Floss For Your Target clientele

Customers often struggle to find the perfect type of floss for teeth cleaning. How to select the most suitable and comfortable floss type for teeth cleaning is never about just choosing one floss type, it is about knowing the slight differences in your tooth gaps and using the right type of floss for those tooth gaps. Therefore, in order to clean and floss your whole mouth, you may need more than one type of floss to get the job done and attain the most desirable and comfortable flossing experience.

For our floss materials, we use synthetic fibers as they have desirable and consistent properties such as high tenacity and high resistance to abrasion and breakage. They are also less prone to be affected by environmental factors such as moisture, bacteria, mildew, etc. We also provide natural fibers upon request.

This is our classic floss. We have been offering this floss on the market for 3 decades. It comes in waxed or unwaxed versions with various flavors to choose from. The floss thread looks fluffier than other types of floss and absorbs liquids easily. When the floss is soaked with liquids, it expands and fills up the spaces between teeth and thus helps bring out food particles. It is intended for people with standard to moderate tooth gap width.

Our charcoal floss is made of the same material as our classic polyester threads with its unique liquid absorption property. The charcoal additive provides a hint of odor absorbent charcoal to help reduce unpleasant breath. It also comes in waxed or unwaxed versions and additional flavor coating is available. It is intended for people with standard to moderate tooth gap width.

Our polyester nylon thread is most popular and sold among our Japanese clients. It is made of a different type of polyester material than our classic polyester threads. It adds a slight luster to the finish of the threads, making it look shiner and glossier than our classic polyester threads. It slides smoothly and is shred and break resistant. It comes with round shaped thread and in waxed or unwaxed versions. Additional flavor coating is available. It is intended for people with standard to moderate tooth gap width.

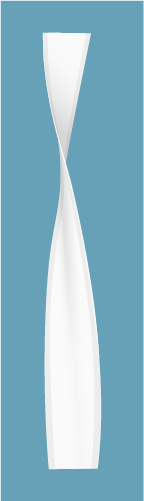

Our Polytetrafluorethylene, or PTFE, thread has gained popularity in the dental hygiene market in recent years. It is the same material used in high-tech Gore-Tex fabric. It is made of monofilament, which creates a shred-proof barrier. The thread has a flat and wide band finish, which creates a larger contact area between teeth. The PTFE material slides easily between teeth and is less likely to shred or break compared to other standard polyester floss. It comes with various flavor coatings. It is intended for people with all kinds of tooth gap widths and shapes.

Choice Of Floss Dispenser Styles

We offer two main dispenser materials for storing floss: plastic dispensers and cardboard dispensers. For plastic dispensers, we currently provide 9 different design styles with various color combinations. We offer dispenser mold design upon request. We also offer 100% biodegradable materials to substitute for our plastic made floss dispensers.

For our environmentally friendly cardboard dispensers, cardboard shape and style designs are flexible based on your market needs. The floss will be wrapped in a water-resistant and 100% biodegradable plastic wrap to ensure product hygiene prior to packaging it into a cardboard dispenser.

For our floss cutter, we use stainless steel materials to ensure that it is durable and sanitary. The floss cutter fits perfectly with our dispensers to provide a clean, easy, and smooth cut of the floss thread.

Packaging Options

We offer three different packaging options for our floss dispensers: HSC (heat sealing card) style blisters, clamshell style blisters, and cardboard style dispensers.

For the HSC style blisters, a coated paper card is sealed to the blister with heating technique to ensure a secure seal. For clamshell style blisters, a coated paper card is inserted in the blister, and then the top and bottom of the clamshell blister are closed with a heat-sealing technique to ensure the secure seal.

All of our blisters are made of recyclable PET materials and our cardboard style dispensers are made of 100% paper based recyclable materials. We are currently working on developing 100% biodegradable materials to substitute for our PET made transparent blisters.